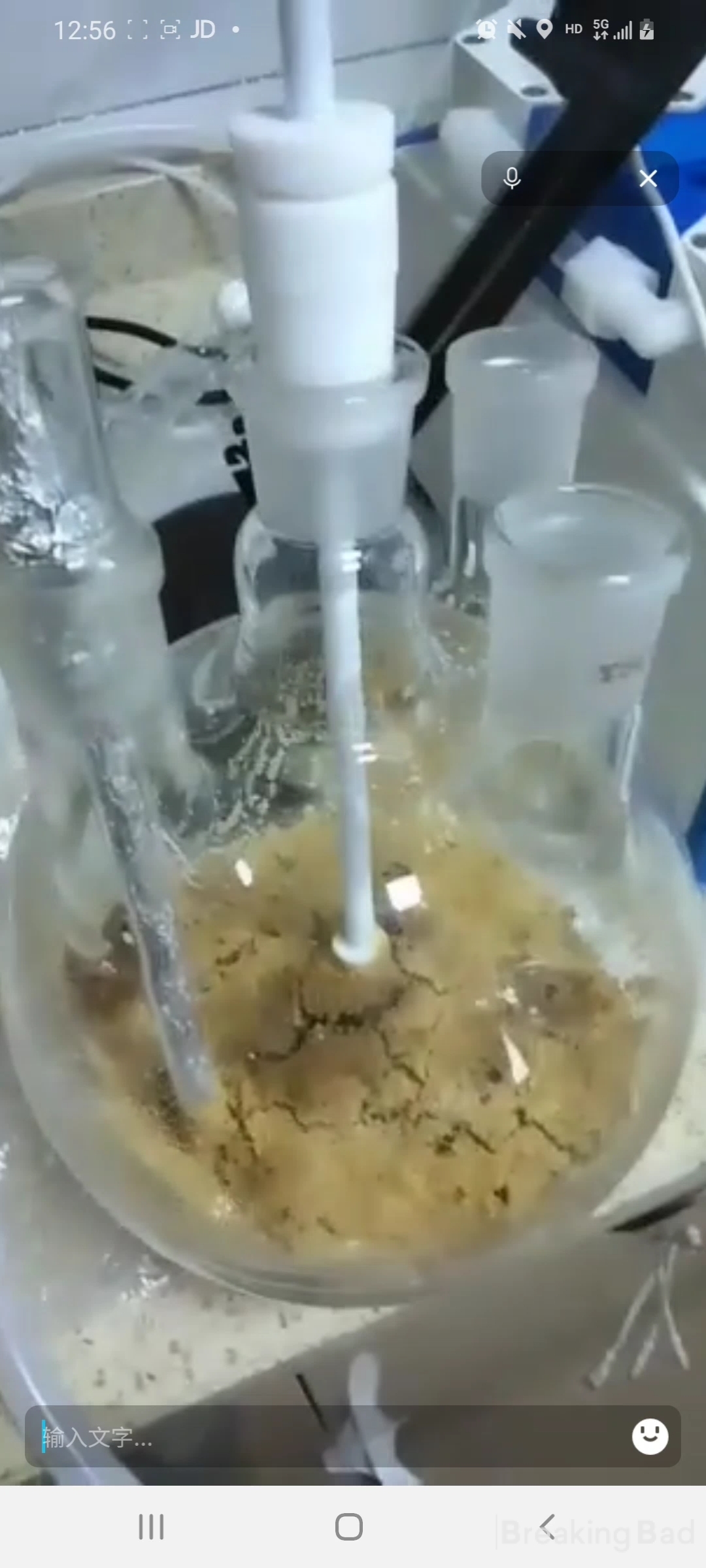

I encountered a problem. I followed the article. After adding sodium ethoxide, I stirred for an hour under a strict anhydrous environment below 10°C. After that, I started to raise the temperature to 60°C to prepare for the option of stirring for an hour. But after a little heating, the temperature in the device spontaneously rose out of control and quickly, and after only a few minutes, my thermometer showed a breakthrough of 130°C, so I want to ask, is this normal? Has anyone encountered it?The first picture is the process of stirring for 1 hour below 10°C after adding sodium ethoxide. I inserted a drying tube filled with anhydrous magnesium sulfate on the device to maintain anhydrous conditions. Since my circulation device can only cool down, I transferred the second stage of heating to the flask. The heating method is oil bath heating, but I just used the temperature of 65°C for a few minutes, and the temperature in the flask was out of control. As it rises, the thermometer shows that it exceeds 130 ℃ very quickly, so fast that I don't even have time to start the condensate water cycle in the condenser pipe, and then it becomes the state in the second picture.

G.Patton

Optional: As an option, an external gradual heating is set up to 60°С. With this method, the reaction yield will be reduced. A reflux condenser is installed on the reactor. RM is stirred at 60°С for additional 1 h. A heating is carried out with help of a reactor jacket and a thermostat.

Last edited by a moderator:

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,422

- Solutions

- 3

- Reaction score

- 2,412

- Points

- 113

- Deals

- 1

I encountered a problem. I followed the article. After adding sodium ethoxide, I stirred for an hour under a strict anhydrous environment below 10°C. After that, I started to raise the temperature to 60°C to prepare for the option of stirring for an hour. But after a little heating, the temperature in the device spontaneously rose out of control and quickly, and after only a few minutes, my thermometer showed a breakthrough of 130°C, so I want to ask, is this normal? Has anyone encountered it?The first picture is the process of stirring for 1 hour below 10°C after adding sodium ethoxide. I inserted a drying tube filled with anhydrous magnesium sulfate on the device to maintain anhydrous conditions. Since my circulation device can only cool down, I transferred the second stage of heating to the flask. The heating method is oil bath heating, but I just used the temperature of 65°C for a few minutes, and the temperature in the flask was out of control. As it rises, the thermometer shows that it exceeds 130 ℃ very quickly, so fast that I don't even have time to start the condensate water cycle in the condenser pipe, and then it becomes the state in the second picture.

View attachment 12911 View attachment 12912

Hello, has the self-heating happen violently or slowly? It is quite interesting.After that, I started to raise the temperature to 60°C to prepare for the option of stirring for an hour. But after a little heating, the temperature in the device spontaneously rose out of control and quickly, and after only a few minutes, my thermometer showed a breakthrough of 130°C, so I want to ask, is this normal? Has anyone encountered it?

↑View previous replies…

Ra226Have you tried to change water layer density by NaCl? It would be cheaper than DCM extraction.

Can you link this potent?

G.Patton

Ra226

G.PattonThis is a patent applied for in China. It seems that the scope of validity is only in China, and there is no English version of the full text, so I did not find the DOI number of this patent. The original text is written in Chinese, and the publisher is from Modern Times, Xi'an City, Shaanxi Province, China Institute of Chemistry, the phone number and email address left by the author are 029-88291460 and [email protected]. But you can pay attention to the content I will post next. Once I verify the reliability of this process, I will post all the detailed processes and precautions. This will take about a week or so from now.

G.PattonIf you need it urgently, I can translate the operation part of the original text and send it to you in private chat. But from a responsible point of view, please do not publish it on the forum before verifying its reliability.

Ra226Just post the patent, your asking for help on a patent no one can see

G.PattonI have published the patent process and practice.

bbgate.com

bbgate.com

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,422

- Solutions

- 3

- Reaction score

- 2,412

- Points

- 113

- Deals

- 1

I did it again yesterday, this time the reaction is normal, but I think the yield will be low as far as the process is concerned. Finally, after adding ice water and standing for an hour, there is no obvious layering, so I use dichloromethane The mixture was extracted and I will analyze this extract today and post the results later. In addition, I just bought a patent for this process. The conditions and operations seem to be simpler and more optimized than your article. It shows that benzaldehyde (CAS 100-52-7) and methyl 2-chloropropionate (CAS 17639- 93-9) to the total yield of purified P2P is as high as 82.9%. I have already purchased related reagents and will try it in a few days

Finally, after adding ice water and standing for an hour, there is no obvious layering, so I use dichloromethane

Can you link this potent?

In addition, I just bought a patent for this process.

Last edited:

Have you tried to change water layer density by NaCl? It would be cheaper than DCM extraction.

Can you ling this potent?

I guess the sodium chloride may not be effective anymore, because when I use dichloromethane to extract, the dichloromethane is abnormally in the upper layer, which means that the density of the water layer is already very high, and the sodium chloride may no longer be able to extract it. Increase density.Also, since I have a rotary evaporator that makes large-scale solvent recycling possible, I don't incur much cost in using solvent extraction reagents in large quantities.Have you tried to change water layer density by NaCl? It would be cheaper than DCM extraction.

regarding the patent, I found a patent published in 2009 and bought it. Its process looks very mature and simple. I plan to try this method after the added reagents arrive. The raw materials are still benzaldehyde and 2 - methyl chloropropionate.Can you ling this potent?

G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,422

- Solutions

- 3

- Reaction score

- 2,412

- Points

- 113

- Deals

- 1

I guess the sodium chloride may not be effective anymore, because when I use dichloromethane to extract, the dichloromethane is abnormally in the upper layer, which means that the density of the water layer is already very high, and the sodium chloride may no longer be able to extract it. Increase density.Also, since I have a rotary evaporator that makes large-scale solvent recycling possible, I don't incur much cost in using solvent extraction reagents in large quantities.

regarding the patent, I found a patent published in 2009 and bought it. Its process looks very mature and simple. I plan to try this method after the added reagents arrive. The raw materials are still benzaldehyde and 2 - methyl chloropropionate.

Can you write full name, number or/and doi please?I found a patent published in 2009 and bought it.

Can you write full name, number or/and doi please?

Can you write full name, number or/and doi please?

- Joined

- Dec 16, 2022

- Messages

- 86

- Reaction score

- 16

- Points

- 8

This is a patent applied for in China. It seems that the scope of validity is only in China, and there is no English version of the full text, so I did not find the DOI number of this patent. The original text is written in Chinese, and the publisher is from Modern Times, Xi'an City, Shaanxi Province, China Institute of Chemistry, the phone number and email address left by the author are 029-88291460 and [email protected]. But you can pay attention to the content I will post next. Once I verify the reliability of this process, I will post all the detailed processes and precautions. This will take about a week or so from now.

Can you write full name, number or/and doi please?

Patented process from benzaldehyde to BMK glycidyl ester to P2P

This article provides you with a patented synthesis process from benzaldehyde to BMK glycidyl ester to P2P. This process comes from a patent published in 2009. The original text used 4-methoxybenzaldehyde to synthesize 4-methoxyphenylacetone. I replaced it with benzaldehyde to synthesize...

bbgate.com

bbgate.com